Blog

Industry 5.0: What it is, key differences, and its impact on industrial maintenance

Industry 5.0 represents the next evolution in industrial digitalization. While Industry 4.0 was defined by automation, IoT, and data analytics, this new phase expands the landscape by integrating machine intelligence with human decision-making capabilities. In this model, collaboration between people and smart technologies becomes the core of production and maintenance strategies.

In the context of asset management and predictive maintenance, Industry 5.0 not only reduces unexpected failures but also enhances operational reliability, boosts productivity, and improves worker safety. Additionally, personalized interventions, energy efficiency, and data-driven analysis become fundamental pillars for achieving higher asset availability.

In this article, we’ll explain what Industry 5.0 is, how it differs from Industry 4.0, the pillars that support this new model, its impact on maintenance, and the practical benefits for operations. We’ll also show how Dynamox supports companies in this transition, offering sensors, digital platforms, and AI applied to asset reliability.

What is Industry 5.0?

Industry 5.0 is the new industrial paradigm that follows Industry 4.0, with its main characteristic being the collaboration between humans and intelligent machines. While the previous phase prioritized large-scale automation, the focus now is on combining the analytical power of technology with human creativity, experience, and strategic decision-making.

In this model, industrial IoT, artificial intelligence, and advanced data analytics remain essential — but no longer operate in isolation. Instead, they are integrated into collaborative processes where operators and engineers use continuous data to adjust production and maintenance strategies in a personalized way.

Therefore, Industry 5.0 doesn’t replace people — it places them at the center of decision-making. Technology in maintenance ensures predictability and efficiency, while professionals apply critical thinking and contextual knowledge to increase asset reliability, improve operational sustainability, and promote safer, more efficient management.

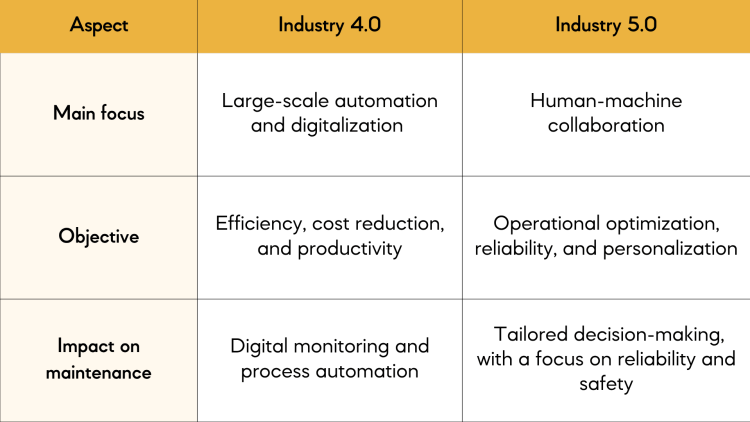

What’s the difference between Industry 4.0 and Industry 5.0?

Industry 4.0 revolutionized industrial production by introducing technologies such as IoT, advanced automation, big data, and artificial intelligence. Its core goal was to digitize processes, increase efficiency, and reduce costs through machine-to-machine and system connectivity.

Industry 5.0 doesn’t replace this model — it expands it. The focus now shifts to human-machine collaboration, with greater emphasis on personalization, AI-powered expert assistants, productivity optimization, and asset reliability. In this phase, technology provides continuous insights, while the human factor drives strategic decision-making, adding context and adaptability to the process.

In short, while Industry 4.0 emphasizes automation and digitalization, Industry 5.0 seeks to balance technological efficiency with human values — ensuring safer, more productive, and data-driven operations.

Check out the comparison table below:

What are the pillars of Industry 5.0 in maintenance?

Industry 5.0 extends the reach of digital transformation by incorporating values such as operational sustainability, personalization, and collaboration. In maintenance, this translates into pillars that connect technology and human expertise to enhance asset reliability and optimize resources.

Operational reliability

In this scenario, reliability becomes more than a goal — it’s a strategic pillar. By combining IoT sensors, artificial intelligence, and predictive analytics, maintenance teams can reduce unexpected failures, increase asset availability, and improve return on investment.

Productivity, sustainability, and energy efficiency

Another key pillar of Industry 5.0 is the pursuit of greater productivity, sustainability, and energy efficiency. In maintenance, this means applying technologies that extend equipment lifespan, reduce waste, produce more with less, and optimize energy consumption. Each intervention goes beyond corrective action and contributes to environmental and corporate responsibility goals.

Personalization and data-driven decision-making

In Industry 4.0, decisions were largely automated. In Industry 5.0, data-driven decision-making is enriched by human experience: people and AI work side by side to identify faults, assess asset criticality, and define the most appropriate approach — considering the plant’s operational reality.

Maintenance strategies and Integration with MPC (Maintenance Planning and Control)

Finally, Industry 5.0 strengthens the integration between technology and MPC (Maintenance Planning and Control) processes. This includes aligning reliability metrics — such as MTBF, MTTR, and availability — with preventive, predictive, and reliability-centered maintenance (RCM) strategies. The result is more precise, connected, and efficient management.

How Industry 5.0 impacts predictive maintenance

Industry 5.0 enhances predictive maintenance by combining advanced digital technologies with human decision-making. In this way, collected data becomes actionable knowledge for asset reliability and management. Below are the key impacts:

IoT and smart sensors

The first major impact comes from the use of industrial IoT and smart sensors — such as Dynamox’s DynaLoggers. These devices enable continuous monitoring of vibration, temperature, and operating conditions. The data collected allows for early fault detection and scheduling of interventions before they escalate into unexpected downtime.

Artificial intelligence for diagnostics

AI in maintenance analyzes large volumes of operational data, identifies degradation patterns, and suggests automatic fault diagnoses. Unlike general-purpose AI, these are algorithms specialized in predictive maintenance, trained to interpret the operating conditions of assets — like DynaDetect, Dynamox’s AI model integrated into Dynamox Platform.

In Industry 5.0, these tools become even more relevant by reducing analysis time, increasing diagnostic accuracy, and allowing engineers and maintenance managers to focus on strategic decision-making.

Would you like to dive deeper into this topic?

Watch Episode 14 of DynaTalks*, about the application of artificial intelligence in industry featuring Danilo Braga (vibration analysis expert), Cristiano Schwening (DynaDetect product manager), André Spillere (development coordinator), and Leondras da Cunha (vibration analyst at Dynamox). *Please note: This content is presented in Brazilian Portuguese. We’re working to make all content available in your language. In the meantime, to enjoy the full experience, please enable automatic subtitles in your browser or directly in the YouTube player.

Context-rich, assisted decision-making

In Industry 4.0, many decisions were automated. Industry 5.0 prioritizes assisted decision-making, where engineers and technicians use reliable data from IoT and AI to personalize maintenance actions. This approach ensures that factors like asset criticality, fault history, and operational context are considered — resulting in more effective, tailored strategies for each plant.

Predictability and fewer unexpected failures

With the integration of IoT, AI, and continuous analysis, predictive maintenance reaches a new level. The result is greater intervention predictability, a significant reduction in unexpected failures, increased asset availability, and stronger support for maintenance professionals. Ultimately, Industry 5.0 builds on the foundations of Industry 4.0 and introduces a strategic leap: producing more with less, and making decisions based on data, context, and human insight.

Which are the practical benefits of Industry 5.0 for maintenance?

Industry 5.0 translates technology into operational results. By combining industrial IoT, specialized AI, and human expertise, maintenance teams gain precise control over risks, costs, and asset availability. união de IoT industrial, IA especializada e a expertise humana, a manutenção passa a controlar riscos, custos e disponibilidade com precisão mensurável. Here are the most impactful benefits for day-to-day operations:

Cost reduction and increased availability

Industry 5.0 reduces both direct and indirect costs by anticipating failures and planning interventions based on asset health. By detecting early degradation, teams can extend MTBF and shorten MTTR through standardized procedures and well-defined maintenance windows. As a result, availability increases while expenses related to overtime, emergency shipments, and production losses decrease.

Greater safety for operators

Industry 5.0 also improves operational safety by reducing field exposure. Continuous monitoring and remote diagnostics minimize entry into hazardous areas, hot work, and interventions on moving equipment. Data-driven scheduling enhances lockout/tagout (LOTO) procedures, reducing the need for on-site interventions.

Sustainable asset management

From an environmental perspective, Industry 5.0 supports energy efficiency and extended equipment lifespan. Algorithms detect imbalance, misalignment, and poor lubrication — all of which increase friction and energy consumption. By addressing these root causes, assets consume less kWh/ton, operate cooler, and experience less wear, reducing waste and premature replacements. This strategy positively impacts energy intensity, component disposal, and lifecycle emissions.

Maintenance maturity evolution

The 5.0 model accelerates the maintenance maturity journey — from time-based (preventive) to condition-based (predictive), and eventually to prescriptive recommendations. In this scenario, teams integrate RCM (reliability-centered maintenance), root cause analysis, fault libraries, and maintenance planning into a closed learning cycle. To support this evolution, it’s important to standardize fault taxonomies, ensure data quality, and monitor process KPIs.

Attracting and retaining technical talent

Finally, Industry 5.0 improves the technician experience. Mobile tools, digital checklists, operational dashboards, and decision assistants reduce repetitive tasks and increase technical autonomy. This helps organizations capture knowledge, reduce reliance on individual expertise, and offer data-driven training paths.

Which are the challenges in implementing Industry 5.0?

The transition to Industry 5.0 in industrial maintenance is not just technological — it requires structural, cultural, and managerial changes. Despite proven benefits in productivity, reliability, and sustainability, several barriers still hinder full adoption of this new paradigm.

Cultural barriers and team training

The first challenge lies with people. Many teams are still accustomed to reactive or traditional preventive practices, leading to resistance against sensors, algorithms, and digital platforms. Industry 5.0 demands professionals skilled in data analysis, reliability, and digital integration. Overcoming this requires continuous training and building a data-driven culture where technology is seen as an ally, not a replacement.

Integration of legacy and new systems

Another common challenge is the coexistence of legacy systems (spreadsheets, local software, outdated CMMS) with new digital platforms based on IoT and AI. Secure and reliable integration between these layers is essential to avoid redundancy, data loss, or traceability issues. Open APIs and modular architectures play a key role in enabling maintenance to evolve toward the 5.0 model without discarding previous investments.

Technology investment and ROI

Implementing Industry 5.0 requires initial investments in IoT sensors, gateways, analytics platforms, and technical training. Although gains in MTBF, MTTR, and availability are well-documented, many companies still struggle to calculate the ROI of digital maintenance. Starting with pilot projects on critical assets is recommended — measuring cost per asset, failure reduction, and production impact before scaling the solution across the plant.

Data governance and cybersecurity

Industry 5.0 increases reliance on continuous data, making cybersecurity a strategic requirement. Data leaks or tampering can compromise diagnostics and pose serious operational risks. In this context, Dynamox follows international information security standards and is certified in ISO 27001, ISO 27701, ISO 27017, and ISO 27018 — reinforcing the reliability of its solutions and ensuring full protection of maintenance data.

How does Dynamox support the journey toward Industry 5.0?

The evolution toward Industry 5.0 demands reliable, secure, and integrated solutions capable of transforming data into actionable intelligence for maintenance. Dynamox offers a complete ecosystem to support your journey in this new industrial landscape.

DynaLogger sensors enable continuous monitoring of critical assets, allowing early fault detection before they impact production. DynaPortable adds flexibility for field inspection routines, expanding predictive maintenance coverage. These devices connect to DynaGateway, which automates data collection, ensuring traceability and accuracy.

All data flows into Dynamox Platform, where intuitive dashboards, structured reports, and advanced AI algorithms — such as DynaDetect — turn raw data into automatic fault diagnostics. This empowers maintenance teams to anticipate issues, plan interventions with precision, and increase asset availability.

Additionally, the system integrates via API with CMMS and ERP systems, ensuring maintenance data is connected to corporate management. This alignment allows reliability indicators to support strategic operational goals. The entire Dynamox ecosystem is backed by international quality and security certifications: ISO 9001, ISO 27001, ISO 27701, ISO 27017, and ISO 27018, reinforcing our commitment to reliability and cybersecurity.

Take your maintenance to the next level with Dynamox. Talk to our specialists and discover how to apply Industry 5.0 to increase the reliability, availability, and safety of your assets.

FAQ – Key questions about Industry 5.0

What’s the difference between Industry 4.0 and Industry 5.0?

Industry 4.0 focused on large-scale automation, machine connectivity, and massive data analysis. Industry 5.0 expands this concept by placing humans at the center — combining IoT, artificial intelligence, and predictive maintenance with human experience and judgment. The result is a more productive, sustainable, and personalized process.

How does Industry 5.0 improve maintenance reliability?

By integrating smart sensors, specialized AI, and assisted decision-making, Industry 5.0 increases fault predictability, extends MTBF, reduces MTTR, and boosts asset availability. Maintenance shifts from being merely corrective to becoming strategic and data-driven.

Which sectors benefit most from Industry 5.0?

Industry 5.0 delivers significant gains for sectors with critical assets and continuous processes, such as mining, steelmaking, agribusiness, and energy.

However, the benefits extend beyond these industries. Many sectors are increasingly adopting industrial IoT, artificial intelligence, and predictive maintenance to improve reliability, reduce costs, and meet growing regulatory demands.

What changes for maintenance teams in practice?

Maintenance teams become more analytical and strategic. Their routines evolve from manual inspections and corrective orders to continuous monitoring, digital checklists, automated diagnostics, and data-driven planning. This reduces repetitive tasks and enhances technical autonomy.

Is Industry 5.0 already a reality or still a future trend?

Industry 5.0 is already a reality in companies using IoT sensors, integrated platforms, and AI to support decision-making. However, full adoption still depends on overcoming cultural barriers, system integration challenges, and digital maturity. Over the coming years, this model is expected to become standard in asset management strategies.

Success cases

Real cases of partners using the Dynamox Solution